Td5 Datalogger updates

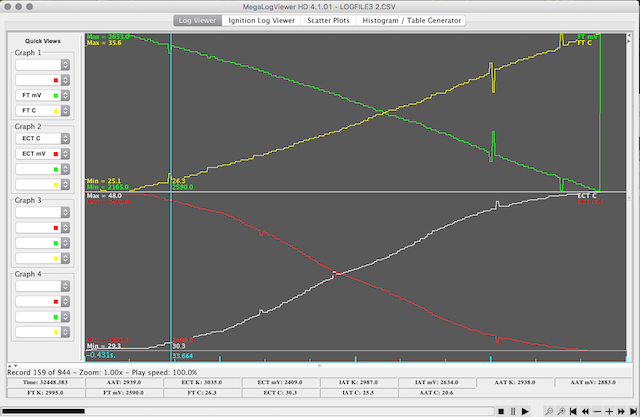

I've come to something of a Catch 22 where I need detailed logging to properly document and verify the waste gate modulator, and the code that handles torque reduction requests from the auto gear box before I can post details of the maps. On the other hand, if I work on the datalogger nothing much happens on the website.

The combination of changes to the Microchip tool chain which caused issues with my old code, a failed hard drive which lead to the discovery that the Microchip peripheral library installer does not work on current versions of macOS, and the need for a rethink and rewrite has meant the datalogger has been out of action since late December.

When I was playing around with the VAGCOM adapter and Python earlier in the year I had ported//rewritten part of my C code and found that using a publish and subscribe framework solved a few of the issues I'd run into. As a result of that little "ah ha" moment and the hassle of dealing with the Microchip libraries I've been working on writing and unit testing peripheral drivers and a publish & subscribe framework in C.

Over the past few weeks I've been progressively bolting together the code that manages the communications with the Td5 ECU.

The way I've decided to approach this is to look at the ISO14230 docs and build a module that handles the startCommuncations, sendData and stopCommunications commands as the base of the logger/interface. That section is now working quite well and at this stage only requires some additional error handling to deal with cases where the ECU response times out mid-message.

From that base I've been working on adding a command interface and USB interface. The idea is to provide a basic set of ELM-like AT commands to configure the settings from default. The current defaults for "pass through" operation are set to connect to a Td5 ECU in manufacturer specific diagnostic mode - Testbook diagnostics in other words.

In practice this means you can hook up the interface and send requests without worrying about the underlying communications protocols. This is similar to how the ELM327 operates.

This is a short demo of the pass through mode, operating over a serial usb connection. The delay between hitting return on the "21 01" command and the response includes the time taken to connect and authenticate to the ECU.